|

|

||

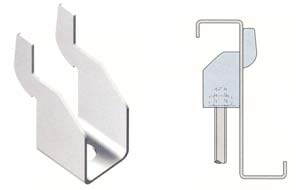

Type WF - WebFix

Type WF - Webfix

DescriptionAn ingenious method of suspending building services directly from the web of Zed purlins. The WebFix can be used with holes pre-drilled by the manufacturer or drilled on site, and installs in a matter of seconds. Working to a maximum thickness of 4mm for the purlin section the WebFix gives a Safe Working Load of 1 kN when used with a grade 8 nut with a 5: 1 Factor of Safety Installation

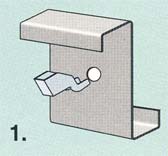

1. Squeeze legs of WebFix together and insert through pre-drilled 18mm hole in purlin. Push product body towards web of purlin until it snaps into place.

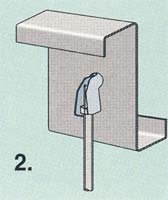

2. Assemble with nut and ensure full thread capture Purlin Angle and Hole Position The WebFix enables threaded rod to hang vertically, allowing for the angle of inclination or cant of the purlin itself

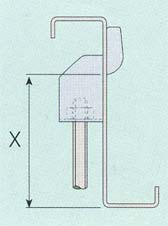

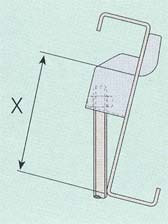

1. Canted Purlins. As the angle of backwards cant increases, the maximum allowable distance X (hole centre to bottom edge of purlin) must decrease. The table on the right shows the maximum value of X at various angles of roof pitch.

2. Inclined Purlins. The WebFix can be adjusted to whatever angle is required. Hole position is not a limiting factor on product installation in this case, however the note * under the table still applies

*To maximise the strength of the purlin section, it is recommended that distance X is as large as possible.

|